Make A Bio Degradable Difference

…Help provide awareness to biodegradable and natural products.

…Be part of the solution to avoid destroying the planet.

…Don’t just make a change, make a difference.

…Omega 3 from heterotrophic fermentation of microalgae

…Optically pure lactic acid in biodegradable plastic PLA

…Cannabinoid (CBD) oil extraction without the use of high-temperature solvents

…Any oilseed extraction process that currently uses solvents

…the delivery of biodegradable plastic ingredients at close to petrochemical prices.

…lowering CO2 emissions from the food, cosmetic and bio-based industries.

…producing the lowest cost Omega-3 oil on the planet to counter over-fishing of our oceans.

- Bacteria 25%

- Process Engineering 50%

- Enzymatic Extraction 75%

- Commercial Production Site 100%

Game Changing - Operational Costs Savings

Low CapEx Cost - Drop In Solution

Saves Energy, Reduces CO2

Bio Degradable Plastic Production

History of Cellulac

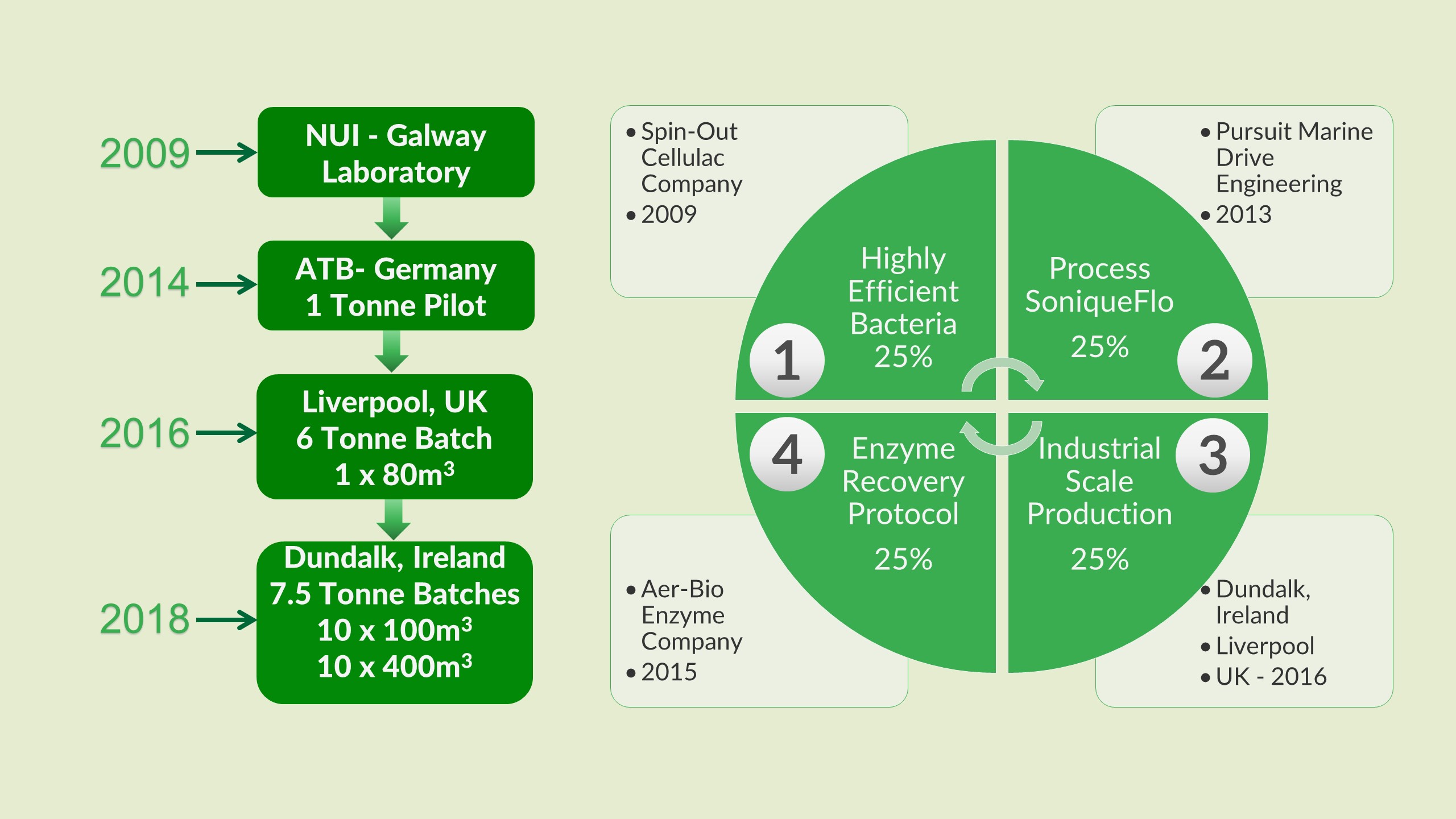

In 2009 Patrick Walsh was a Professor at the National University of Galway, Ireland. His vision was to reduce the amount of energy in the production of biodegradable plastic. This biodegradable plastic ingredient is lactic acid. Used as a food preservative, curing agent, and flavoring agent. It is also an ingredient in processed foods, used during meat processing.

When broken down, the bio-degradable plastic ingredient converts back to CO2 and water.

Bacteria are easy to explain if you recall the 1984 and 1990 movie “Gremlins”. If you spilled water on them, they multiplied. Just like Gremlins, Lactic Acid and Micro-algae multiply in water.

Bacteria are easy to explain if you recall the 1984 and 1990 movie “Gremlins”. If you spilled water on them, they multiplied. Just like Gremlins, Lactic Acid and Micro-algae multiply in water.

2012 - New Management

New management were brought in. Even with the vision and the size of EU grant, finding €9 million for a pilot plant, that was never going to break-even, let alone be profitable, was equally never going to be built.

The team, which came from a previous successful company, Alltracel Pharmaceuticals, altered the direction and mission to address the glaring lack of infrastructure needed to commercialize the technology.

2013 - 1st Transaction

There is a need to punch the living daylights out of the Gremlin-like bacteria and micro-algae. This begins the release of oils and bio-plastic polymer ingredients into a soup-like mixture.

Some of you will know the history of Pursuit Marine Drive. This was a former subsidiary of Pursuit Dynamix PLC (PDX). If so, you are probably wondering, why on earth did you buy a failed company that had blown through £68 million GBP. Right?

Well, the portion of £68m, spent in R&D, provided Cellulac with a unique game changing platform. This was the engineering equivalent of the Pfizer side-effect for their heart treatment, turned erectile dysfunctional drug, Viagra.

SoniqueFlo was originally designed as an industrial scale heat-exchanger that softened up grains before food, ethanol and beer production. Now, that same technology works 10 times more efficient. It smashes up softer cells on the recovery end of bio-oil and bio-plastic ingredient production.

It is like having millions of mini-Conor McGregors compressed into each SoniqueFlo reactor punching the oils and bio-plastic ingredient out of the Gremlin-like Bacteria and Micro-algae.

The beauty of this industrial scale solution is that the technology was already field tested. It has been fully operational in 25 production facilities across the food, bio-fuel and alcohol industries since 2010. This is where we get the benefit of having £68m spent before we acquired the technology.

2013 - 2nd Transaction

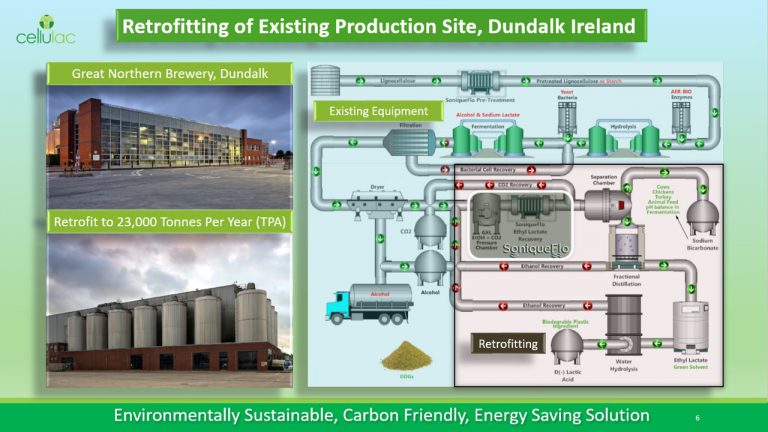

It is the former Diageo, Harp Lager production plant in Dundalk, Ireland. A state-of-the-art facility, fully automated, food and beverage grade facility.

2015 - 3rd Transaction

These (Pac-Man-like) enzymes are proteins that consume the outer layers of oil-bearing cells. Cellulac worked with Aer-Bio on a combination of the SoniqueFlo and Enzymes since early 2014. The result is a commercial scale low-carbon production solution for non-fish Omega-3 oils.

These (Pac-Man-like) enzymes are proteins that consume the outer layers of oil-bearing cells. Cellulac worked with Aer-Bio on a combination of the SoniqueFlo and Enzymes since early 2014. The result is a commercial scale low-carbon production solution for non-fish Omega-3 oils.

2016 - First Proven Commercial Scale Production

The finished product has been granted approval as a human food grade product. The first sales of Omega-3 have been delivered to one of the largest food ingredient companies in the world.

2017 - 4th Transaction

Pharmafilter B.V. design, build and install self-contained energy recovery units in hospitals across Europe. They have agreed to purchase our bio-plastic for 5 hospitals each year, for the next 5 years. Hospitals use 600 tonnes of single-use plastic each year. Our bio-plastic reduces the carbon footprint of each hospital.

Our bio-degradable plastic is recycled by Pharmafilter, directly to gas. This gas-energy is burned to heat the hospitals and sterilize their waste water. It is a perfect example of the circular economy.

2018 - Ramp up of Scaled Production

First full year production will be 2019.

Multiple MOU’s have been signed. Production and joint venture opportunities are open to Cellulac in Europe and the US. These are in the ethanol and dairy sectors. Licensing and royalty opportunities exist now we have demonstrated Omega-3 production at scale. This is the first, full scale game-changing, low-carbon production solution available for licensing.

Commercial Scale Production of Omega 3

The Team

Tel: +44 (0)1223 926 660