Daring to Dream Big

The definition of insanity is doing the same thing over and over again and expecting a different result – Albert Einstein

Another 300 million tonnes of plastic every year

Since World War II we have consumed 5 billion tonnes of plastic, much of which has ended up in a landfill or the oceans.

Making ourselves healthier by depleting global fish stocks.

In 2015, a consensus of expert opinion suggested that a recommended minimum daily dose of 500mg the Omega 3 oil requirement for the world population was 1.3 million metric tonnes. The world fish catch is not elastic and we are already at a plateau. Thankfully we are still producing much less than that each year, but demand continues to grow, while fish stocks continue to be depleted.

Daring to think big enough to have an effect

In 2009 Patrick Walsh was a Professor at the National University of Galway, Ireland, had a vision of reducing the amount of energy in the production of biodegradable plastic. This biodegradable plastic ingredient is lactic acid. Used as a food preservative, curing agent, and flavoring agent. It is also an ingredient in processed foods and is used as a decontaminant during meat processing.

When broken down from poly-lactic acid, the lactic acid derived bio-plastic ingredient converts back to CO2 and water.

Humble, or destitute beginnings

By 2012 this small company, now named Cellulac, was €300,000 in debt but had secured €2.8m of EU grants for a pilot plant, with the conditions for the release of the grant be, that industry and investors had to contribute a further €9m.

New management was brought in. Even with the vision and the size of EU grant, finding €9 million for a pilot plant, that was never going to break-even, let alone be profitable, was equally never going to be built.

The team, which came from a previously successful company, Alltracel Pharmaceuticals, altered the direction and mission to address the glaring lack of infrastructure needed to commercialize the technology.

- 25% of the solution, the Bacteria, was in place. Bacteria are easier to explain if I use the term Gremlins. Remember the movies from 1984 and 1990? If you spilled water on them, they multiplied. Just like Gremlins, Lactic Acid and Micro-algae multiply in water. They are incidentally, produced in separate tanks.

- 25% was an industrial scale engineering solution. There was a need to punch the living daylights out of the Gremlin-like bacteria and micro-algae to begin the release of oils and bio-plastic ingredients into a soup-like mixture.

- 25% was a low-cost recovery method. Enzymes are like the 80’s video game of Pac-Man. They consume the ghosts of the Gremlins shell to release the oils and lactic acid.

- The last 25% was a requirement for a production facility that would deliver commercial scale production of the bio-plastic ingredient and Omega-3 oils.

Pulling the pieces together

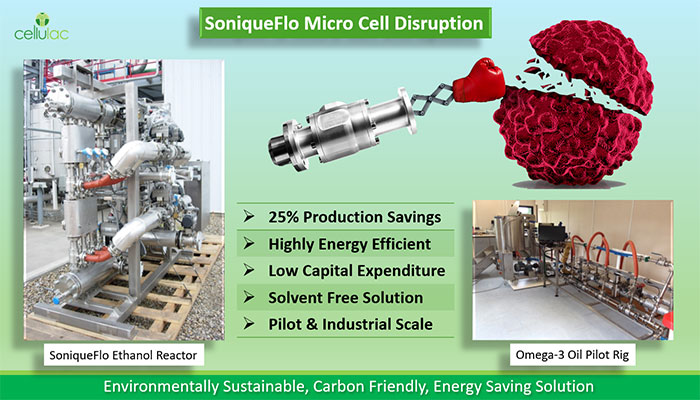

In July of 2013, Cellulac reached the 50% milestone when it acquired the SoniqueFlo technology from Pursuit Dynamics (PDX).

If you know the history of PDX, you are probably thinking, why buy the failed PDX. Right? They had blown through £68 million GBP.

Well, for Cellulac, this was the equivalent of being handed the engineering equivalent of Pfizers side-effect for their heart treatment, turned erectile dysfunctional drug, Viagra.

SoniqueFlo was designed as an efficient heater that softened up grains before food, ethanol and beer production. The same technology worked 10 times better at smashing up softer cells on the recovery, or end, stage of oil and bio-plastic ingredient production.

It was like having millions of mini-Conor McGregors compressed into each SoniqueFlo reactor punching the oils and bio-plastic ingredient out of the Gremlin Bacteria and Micro-algae, preparing them for the final stage.

The beauty of this industrial scale solution is that it was already operationally successful in 25 production facilities across the food, bio-fuel and alcohol industries since 2010.

Later in 2013, Cellulac reached the 75% milestone when it secured access to the 2nd largest brewery in Ireland. This had the output equal to 100 times the size of the original pilot plant that had been the subject of the EU Grant in 2012. It was the former Diageo, Harp Lager production plant in Dundalk, Ireland. A state-of-the-art facility, fully automated, food and beverage grade facility.

The 100% milestone was reached faster than expected in 2015, with the acquisition of Aer-Bio. This was a small Enzyme expression protocol company. They specialized in the recovery of oils from micro-algae and production of Omega-3 using Enzymes (these are Pac-Man-like proteins that consume the outer layers of cells which have oil inside).

Cellulac had worked with Aer-Bio on a combination of SoniqueFlo and Enzymes since early 2014 to deliver a solvent-free production process for Omega-3 oils.

Proven Commercial Scale Production

In 2016, at a UK industry partner site, the conversion from a conventional solvent-based process to a solvent-free process was responsible for an 81% reduction of the downstream recovery cost of Omega-3 oils.

The outcome is a commercial scale solvent-free production process with sales of Omega-3 to one of the largest food ingredient companies in the world.

By 2017, Cellulac has achieved 3 out of these 4 stages:

- Laboratory

- Third-party pilot facility in Potsdam, DE. 1 x 1,000 litre vessel

- Industry Partner commercial scale in Liverpool, UK. 6-Tonne per batch from one 80,000 litre vessel.

- Cellulac production site, Dundalk, IE. 10 x 100,000 litre vessels and 10 x 400,000 litre vessels.There is a lot more going on and you can expect some major news before the end of this year.

[TheChamp-FB-Comments style=”background-color:#f7f7f7;” title=”Leave a Comment”]

Integumen License Ageement

Today, Cellulac announces that it has signed Heads of Terms to enter into a commercial technology agreement with Integumen (LSE: SKIN). In addition, Integumen has conditionally agreed to acquire 9.35% of the issued shares of Cellulac. Gerard Brandon and Camillus...

What are you doing about ocean pollution?

To many people watching Sky News and their #OceanFree Campaign, you would think that removing plastic from the oceans will be enough to resolve the problem. Sadly, this is not the case. The oceans ability to provide food from fisheries and aquaculture is...

Climate Change Our Bit Infographic

[TheChamp-FB-Comments style="background-color:#f7f7f7;" title="Leave a Comment"]

Biomassive Revolution

It's just not your fault What if I were to tell you that it is not your fault that the seas are polluted with plastic that the fish and whales are consuming? In the same way, I can say that it is not your fault that over-fishing is destroying future fish...

Low Energy Microalgae to Biofuel at Commercial Scale

Food and Fuel for the 21st Century Microalgae have come to the attention of the industrial and academic community over recent years because of their ability to harvest the energy of the sun and provide valuable molecules that offer great potential to provide...

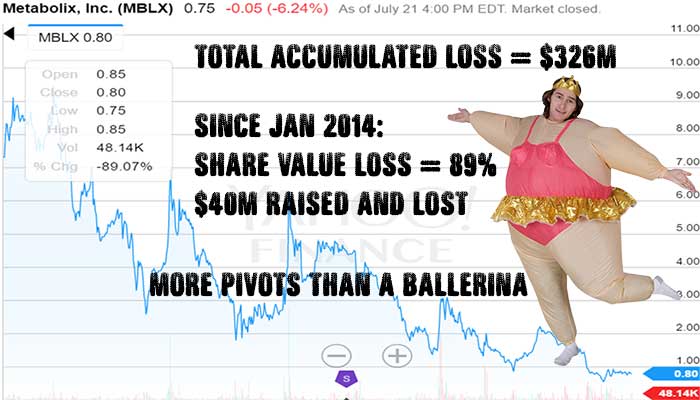

Cellulac Formally Requests Metabolix Shareholders to Consider Merger Proposal

Cellulac merger proposal to Metabolix worth $40m in assets and offtake agreement of $38m rejected in favor of closing biopolymer business and spending $35m over 7 years on crop science project with no revenue. DEAR METABOLIX SHAREHOLDERS London, UK. 25th...

Extracting real value from the Ethanol Industry

Hybrid Solutions There is no need to reinvent a billion dollar wheel of bio-industrial experimental development. True value can be extracted and integrated as hybrid synergistic solutions from the best-in-class of what already exists. Over the last 10...

Corny Problem for EU Sugar Producers

The abolition of sugar quotas in 2017 will have such a profound effect on EU sugar producers, used to super profits under the EU supported Common Agricultural Policy (CAP), that many smaller producers will be subject to consolidation or have to cease...

Big Oil Can’t Alter Climate Change

In a recent major MIT Study (Covert, Thomas, Michael Greenstone, and Christopher R. Knittel. 2016. "Will We Ever Stop Using Fossil Fuels?" Journal of Economic Perspectives, 30(1): 117-38. ) it was shown that approximately 65 percent of global greenhouse gas...

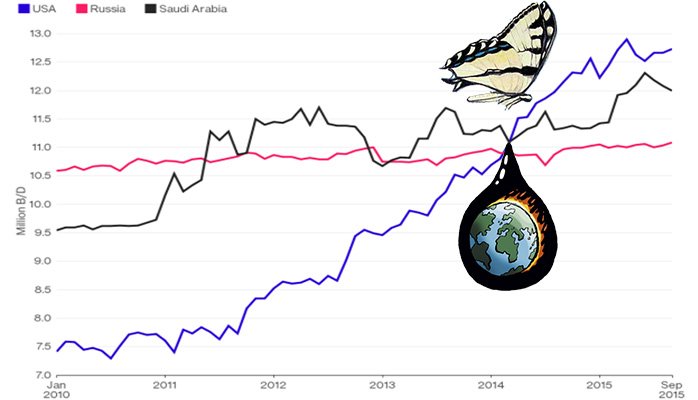

Butterfly Effect of Oil Price on Renewables

The butterfly effect is a concept that small causes can have large effects. Initially, it was used with weather prediction but later the term became a metaphor used in and out of science. Now it can easily be related to a single decision made by a Saudi Oil...

Cellulac Acquires Aer Sustainable Energy (Aer-Bio)

10 fold saving in enzymes, 4 fold increase in algae oils within 2 hours reducing the process costs of Omega-3, animal feed and biofuels Dublin, Ireland, 18th May 2015: Cellulac, the industrial biochemicals company, today announces the acquisition of Aer...

5 year, €35m Pharmafilter Partnership with Cellulac

Partnership delivers 2nd generation bioplastics supply chain solution for hospitals Dundalk, Ireland and Amsterdam, The Netherlands, 30th March 2015: Cellulac, the industrial biochemicals company, and Pharmafilter, a provider of integrated waste management...

Cellulac to Acquire Patent Portfolio and Industrial Biochemical Equipment from Pursuit Dynamics PLC

Cellulac Limited, the industrial biochemicals company, announces the acquisition of Pursuit Marine Drive Limited, a subsidiary of Pursuit Dynamics PLC, subject to shareholder approval. The acquisition includes certain intellectual property rights, test...