Lactic Acid from Lactose Whey - Continuous Production Run

Cambridge, UK. 19 May 2014: Cellulac, the industrial biochemicals company is delighted to announce the world’s first ever industrial level continuous production of lactic acid from deproteinized lactose whey. Our 10 day production run concluded this week and delivered optically pure D(-) Lactic Acid suitable for conversion to bioplastics.

Whey is considered a high volume wastewater obtained as a by-product of the cheese production process following the separation of fat and casein from milk. As it has a high chemical oxygen demand it is considered a major pollution problem for the dairy industry. Cellulac’s cutting edge technology is able to take this by-product and convert it into lactic acid which can be used in the production of bioplastics as well as other industrial chemicals.

Gerard Brandon, CEO of Cellulac, commented;

We are the first company to achieve continuous production of optically pure lactic acid from deproteinized lactose whey at industrial scale. This is a major breakthrough that we will exploit in our Dundalk plant, Ireland, as we build out our Phase 1 production of up to 20,000 tonnes of high specification ingredients. Our resulting lactic acid can be used for industrial strength and heat resistant bioplastics. The use of such 2nd generation alternative source of sugars, in addition to our continuous runs, leads to significant savings in time, productivity, quality, recoverable additives, and ultimately a lower production cost.

“Our innovative solution not only solves a pollution problem for dairy processors, but creates a major value-added product to the agricultural sector in a market deemed to be reliant on commodity prices which are set to come under further pressure from removal of EU Milk Quotas next year.

40% cost saving over first generation Lactic Acid production

Cellulac expect a reduction in cost of production of optically pure Lactic Acid in excess of 40% compared to current approaches that rely on sugar and starch (first generation) feedstocks for a number of reasons.

Feedstocks Tested Since 2007

- The Cellulac bio-production process utilises raw materials that are second generation feedstocks, including lactose whey and lignocellulosic materials (eg straw, spent brewers’ grains, ethanol producers’ distilled dried grains with solubles). These are by products resulting from other commercial or agricultural processes and as such have little intrinsic commercial value, guaranteeing low input costs. By contrast, first generation feedstocks used in alternative bio-production platforms are highly sensitive to commodity price inflationary pressures as a result of their use as basic food crops.

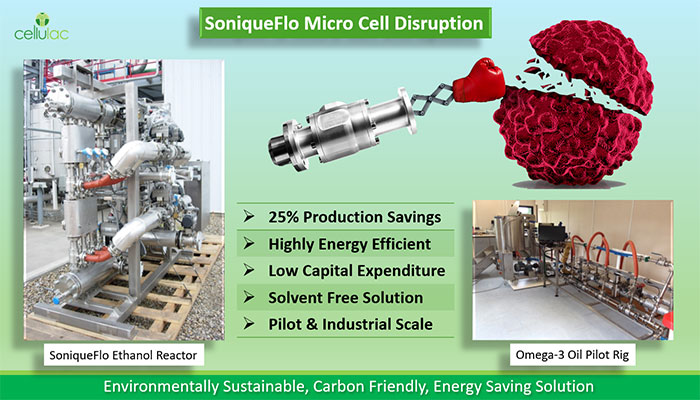

- The Cellulac process significantly reduces the combined cost of energy and enzymes for the conversion of raw feedstocks to fermentable sugars when compared to alternative pre-treatment systems such as steam explosion. This results from the application of the SoniqueFlo™ cavitation technology in the pre-treatment of such feedstocks and the use of cellulac’s proprietary cocktail of enzymes to furnish high yields of both C5 / C6 fermentable sugars for subsequent downstream conversion to biochemicals.

- The Cellulac process removes the majority of the energy costs associated with the downstream processing of fermentation broth to Lactic Acid by the innovative use of supersonic energy and CO2 in SoniqueFlo™ to produce ethyl lactate, an industrial organic solvent derived from Lactic Acid. Conventional processing is highly energy intensive and consumes as much as 67% of the overall cost of Lactic Acid production.

Integumen License Ageement

Today, Cellulac announces that it has signed Heads of Terms to enter into a commercial technology agreement with Integumen (LSE: SKIN). In addition, Integumen has conditionally agreed to acquire 9.35% of the issued shares of Cellulac. Gerard Brandon and Camillus...

What are you doing about ocean pollution?

To many people watching Sky News and their #OceanFree Campaign, you would think that removing plastic from the oceans will be enough to resolve the problem. Sadly, this is not the case. The oceans ability to provide food from fisheries and aquaculture is...

Climate Change Our Bit Infographic

[TheChamp-FB-Comments style="background-color:#f7f7f7;" title="Leave a Comment"]

Biomassive Revolution

It's just not your fault What if I were to tell you that it is not your fault that the seas are polluted with plastic that the fish and whales are consuming? In the same way, I can say that it is not your fault that over-fishing is destroying future fish...

Daring to Dream Big

The definition of insanity is doing the same thing over and over again and expecting a different result - Albert Einstein Another 300 million tonnes of plastic every year Since World War II we have consumed 5 billion tonnes of plastic, much of which has ended...

Low Energy Microalgae to Biofuel at Commercial Scale

Food and Fuel for the 21st Century Microalgae have come to the attention of the industrial and academic community over recent years because of their ability to harvest the energy of the sun and provide valuable molecules that offer great potential to provide...

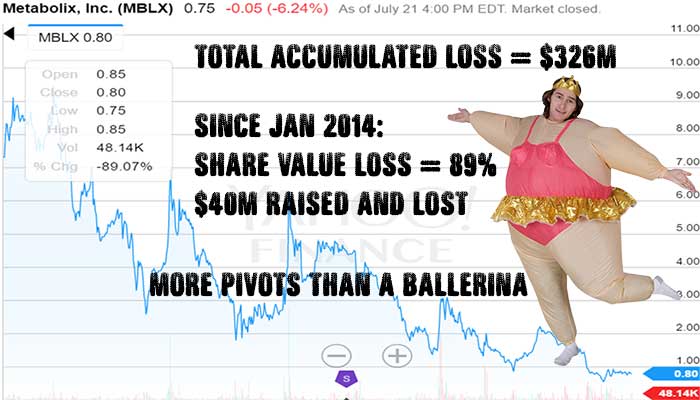

Cellulac Formally Requests Metabolix Shareholders to Consider Merger Proposal

Cellulac merger proposal to Metabolix worth $40m in assets and offtake agreement of $38m rejected in favor of closing biopolymer business and spending $35m over 7 years on crop science project with no revenue. DEAR METABOLIX SHAREHOLDERS London, UK. 25th...

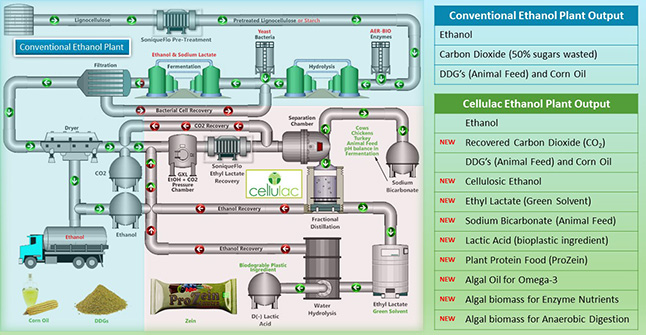

Extracting real value from the Ethanol Industry

Hybrid Solutions There is no need to reinvent a billion dollar wheel of bio-industrial experimental development. True value can be extracted and integrated as hybrid synergistic solutions from the best-in-class of what already exists. Over the last 10...

Have we Reached Peak Biofuel?

Is there really an energy security risk? Former NATO Secretary General Anders Fogh Rasmussen is calling on Europe to increase the production of biofuels from an energy security perspective because of geopolitical risks. This is a tough ask if such increase in...

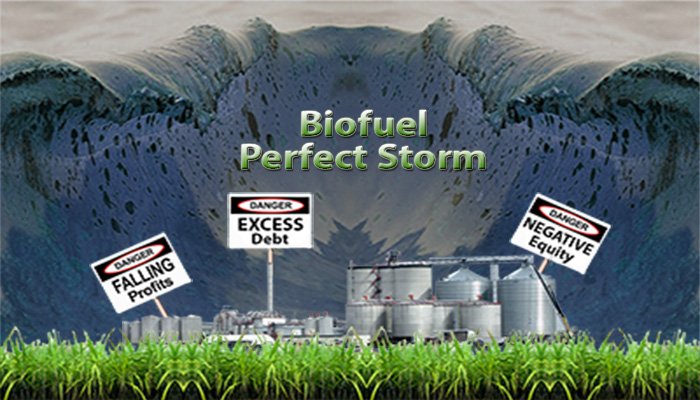

Biofuels Perfect Storm

Biofuels Perfect Storm Since August 2015, ethanol has traded at a premium to gasoline which is unusual by historical standards. This is likely to continue until oil prices rebound into the $45-50 per barrel range. Even with this situation, 2015 ethanol...

Ethanol Industry is not too big to Fail

Phonetically speaking we know the two things that are guaranteed are death and taxes. However debt can be the precursor to death for not just companies, but industries. The ethanol industry, reading through the last 2 years of SEC filings by ADM, indicate that...

High Corn Crush Margin Ethanol Plant Solution

The ethanol industry has only been around for the last few of decades, though in its present state it takes centuries of fermentation knowledge to achieve the same output of ethyl alcohol (ethanol).Today, there are by-products or side-streams, such as distilled...

Corny Problem for EU Sugar Producers

The abolition of sugar quotas in 2017 will have such a profound effect on EU sugar producers, used to super profits under the EU supported Common Agricultural Policy (CAP), that many smaller producers will be subject to consolidation or have to cease...

Big Oil Can’t Alter Climate Change

In a recent major MIT Study (Covert, Thomas, Michael Greenstone, and Christopher R. Knittel. 2016. "Will We Ever Stop Using Fossil Fuels?" Journal of Economic Perspectives, 30(1): 117-38. ) it was shown that approximately 65 percent of global greenhouse gas...

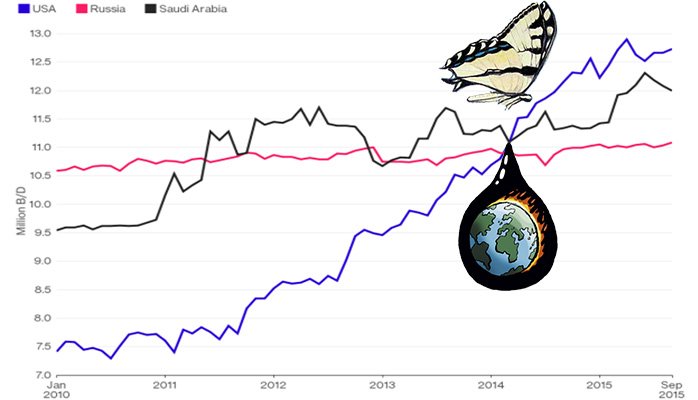

Butterfly Effect of Oil Price on Renewables

The butterfly effect is a concept that small causes can have large effects. Initially, it was used with weather prediction but later the term became a metaphor used in and out of science. Now it can easily be related to a single decision made by a Saudi Oil...

Cellulac Acquires Aer Sustainable Energy (Aer-Bio)

10 fold saving in enzymes, 4 fold increase in algae oils within 2 hours reducing the process costs of Omega-3, animal feed and biofuels Dublin, Ireland, 18th May 2015: Cellulac, the industrial biochemicals company, today announces the acquisition of Aer...

5 year, €35m Pharmafilter Partnership with Cellulac

Partnership delivers 2nd generation bioplastics supply chain solution for hospitals Dundalk, Ireland and Amsterdam, The Netherlands, 30th March 2015: Cellulac, the industrial biochemicals company, and Pharmafilter, a provider of integrated waste management...

Cellulac to Acquire Patent Portfolio and Industrial Biochemical Equipment from Pursuit Dynamics PLC

Cellulac Limited, the industrial biochemicals company, announces the acquisition of Pursuit Marine Drive Limited, a subsidiary of Pursuit Dynamics PLC, subject to shareholder approval. The acquisition includes certain intellectual property rights, test...